Capturing, transporting, and storing CO2 underground might sound like something out of a sci-fi movie.

But here in Norway, we've been engaged in carbon capture for over 20 years and now lead the field with the world's foremost researchers.

The problem is that carbon capture is challenging and expensive.

But 'burningly necessary' if we are to reach our climate goals.

Global warming due to the build-up of greenhouse gases in the atmosphere is changing the world, with carbon dioxide from the burning of oil, natural gas, and coal accounting for two-thirds of global emissions. Time is running out, and one of the immediate solutions to this crisis is to capture CO2 at source and store it deep underground. Although there are critical voices, many countries and experts agree that carbon capture and storage, or CCS, is essential to keep temperatures in check. According to environmental organization Bellona, among others, the Earth will start to boil without CCS.

Norway has the world's oldest carbon capture facility at the Sleipner oil field in the North Sea and is a world leader in CCS technology. If we succeed with large-scale carbon capture, our small country at the top of Europe may play a crucial role in reaching global climate goals. It's no small order; CCS is expensive and technically demanding, and we've not always succeeded. So, it's a huge benefit to be able to test concepts before building.

French engineer Ludivine Le Granvalet Rossvoll is responsible for Kongsberg Digital's LedaFlow software that tests how oil and gas behave in pipelines. They have customers all over the world, saving oil companies as well as the Norwegian state huge sums of money. There is a flood of interest from international stakeholders who have realized that LedaFlow can also be used in the opposite direction. These companies want to help crack the code on how to transport CO2 safely and efficiently from factories on land to reservoirs under the seabed. The gas is compressed into liquid form and transmitted in long pipes, and the Norwegian-developed LedaFlow application can simulate everything that can happen along the way. Data simulation of CO2 transport is new territory, and if everything falls into place, will help pave the way for large-scale CO2 storage.

"Transporting CO2 is different from transporting oil and gas. Firstly, we're sending CO2 in the opposite direction, through pipes into the ground. And believe it or not, it's not the same."

Ludivine Le Granvalet Rossvoll

Product owner, LedaFlow, KONgsberg digital

Earth Captures

At the forefront of the development of large-scale CO2 sequestration are a pair of environmental activists who have infiltrated the business in the hope of saving the planet.

Journalist: Tina Aasen

Illustration: Marius Halvorsen

Photo/video: Björn Audunn Blöndal | Artlist

Kongsberg Digital is the commercial owner of LedaFlow, and French engineer Ludivine Rossvoll works closely on the application with her German colleague, Jonathan Nees. Jonathan is responsible for the company's K-Spice simulator used for testing and training on oil platforms, modeling everything from components in electrical networks to pumps and compressors. The calculation methods are the result of years of research and are now fully synchronized with LedaFlow.

The two engineers both have backgrounds in environmentally friendly industries and joined Kongsberg Digital so that they could make a difference where it really matters. Jonathan started out researching energy efficiency at home in Germany but wanted to do more. "I decided to follow the big processes in the chemicals and oil and gas industries. CCS will help us reach our climate goals," he says. "That's what gets me out of bed every morning."

Ludivine Le Granvalet Rossvoll is the product owner for LedaFlow at Kongsberg Digital and works closely with colleague Jonathan Nees, product owner for the K-Spice simulator.

Environmental agents on a mission

We're boiling the planet

Even COP26 – the latest commitments to reduce greenhouse gas emissions signed by 120 countries – is not enough to meet the Paris Agreement climate target. If complied with, the global temperature is heading for an increase of at least 2.7°C in this century.

If all politically determined measures are implemented, the Intergovernmental Panel on Climate Change (IPCC) reports that the increase in global temperature will be 3.2°C by 2100.

Heading for a 3-4°C increase

Temperature increases of a maximum of 1.5°C by 2100 was the climate goal of the Paris Agreement. It doesn't sound like much, especially here in the north where it's so cold, but Ludivine Rossvoll says there is a lack of understanding regarding the effect of climate change. In 2022, the global average temperature was already 1.15°C higher than pre-industrial levels, and emissions are increasing.

Ludivine explains: "20,000 years ago, the planet was on average 5-6°C colder than today. At that time, large parts of the world were covered by ice and sea levels were so low that you could walk from France to England; there was no English Channel. If emissions continue, we are heading for an increase of 3-4°C. The temperature has already increased more at the poles, leading to sea ice melting, which in turn changes the chemical balance in the ocean. Climate change has a snowball effect, which means we need to work as quickly as possible to get CCS in place."

According to the report "A Future You Don't Want", most plants, trees, and animals will not withstand a temperature increase of 4°C. Ecosystems will collapse worldwide, and both rainforests and boreal forests will die. Only the northernmost parts of the USA, Alaska, Canada, and Europe, the Nordic countries, Russia, southern South America, and Australia and New Zealand will be livable areas for humans. Only here will it be possible to produce food with known agricultural methods. However, extreme weather and periods of drought will make food production challenging even in the north.

Norway has stumbled before with the Mongstad CCS project, which was supposed to clean and store CO2. Then Prime Minister Jens Stoltenberg called it 'Norway's moon landing'. It unfortunately ended in a crash landing; the plant was shelved in 2013 having cost at least 7.8 billion kroner. Carbon capture is a tough nut to crack, but now the industry is trying again, with Equinor at the forefront and the Norwegian government investing heavily in the Langskip and Northern Lights projects. The goal is to capture and store 5 million tons of CO2 under the seabed by 2026. The government is also providing 16.8 billion kroner for CO2 capture and storage from the Klemetsrud waste incinerator in Oslo and the Heidelberg Materials (Norcem) cement factories in Brevik, but there are obstacles; the projects cost more than planned and are currently postponed.

The massive CCS facility at Heidelberg Materials (Norcem) in Brevik under construction.

Image: Heidelberg Materials AG

The simulator models LedaFlow and K-Spice are receiving great interest from international companies. CO2 emissions are an urgent global problem that many actors, both governments and private companies, are trying to solve. Fertilizer producer Yara is also investing in carbon storage, while Equinor wants to make carbon capture profitable. The energy major plans to build a 1,000-kilometer-long pipeline from Europe to the Troll field offshore Bergen, which European emitters can connect to. The goal of the CO2 Highway Europe project is to transport and store large amounts of CO2 beneath the seabed.

Equinor operates the world's oldest CCS project on the Sleipner gas field, pumping a million tons of CO2 under the seabed every year. Around 15 million tons have been stored so far. Since 2008, CO2 has also been captured from a processing plant at Melkøya near Hammerfest, then transported by pipeline to the Snøhvit field for storage. But so far, no one in the world has succeeded in commercializing CCS and making it profitable.

The art of making carbon capture profitable

Norway has stumbled before with the Mongstad CCS project, which was supposed to clean and store CO2. Then Prime Minister Jens Stoltenberg called it 'Norway's moon landing'. It unfortunately ended in a crash landing; the plant was shelved in 2013 having cost at least 7.8 billion kroner. Carbon capture is a tough nut to crack, but now the industry is trying again, with Equinor at the forefront and the Norwegian government investing heavily in the Langskip and Northern Lights projects.

The goal is to capture and store 5 million tons of CO2 under the seabed by 2026. The government is also providing 16.8 billion kroner for CO2 capture and storage from the Klemetsrud waste incinerator in Oslo and the Heidelberg Materials (Norcem) cement factories in Brevik, but there are obstacles; the projects cost more than planned and are currently postponed.

Equinor operates the world's oldest CCS project on the Sleipner gas field, pumping a million tons of CO2 under the seabed every year. Around 15 million tons have been stored so far. Since 2008, CO2 has also been captured from a processing plant at Melkøya near Hammerfest, then transported by pipeline to the Snøhvit field for storage. But so far, no one in the world has succeeded in commercializing CCS and making it profitable.

Det massive CCS-anlegget ved Heidelberg Materials (Norcem) på Brevik under konstruksjon.

Samtidig får simulatormodellene LedaFlow og K-Spice stor interesse fra internasjonale bedrifter. CO2 er et presserende globalt problem som mange aktører, både myndigheter og bedrifter prøver å løse.

Gjødselprodusenten Yara satser også på karbonlagring og Equinor ønsker å gjøre butikk ut av karbonfangst. Equinor planlegger et 1000 kilometer langt rør fra Europa til Troll-feltet utenfor Bergen, som europeiske bedrifter kan koble seg på. Målet med prosjektet CO2 Highway Europe er å transportere og lagre store mengder karbondioksid ved Troll-feltet utenfor Bergen.

The art of making carbon capture profitable

Foto: Heidelberg Materials AG

90 m deep

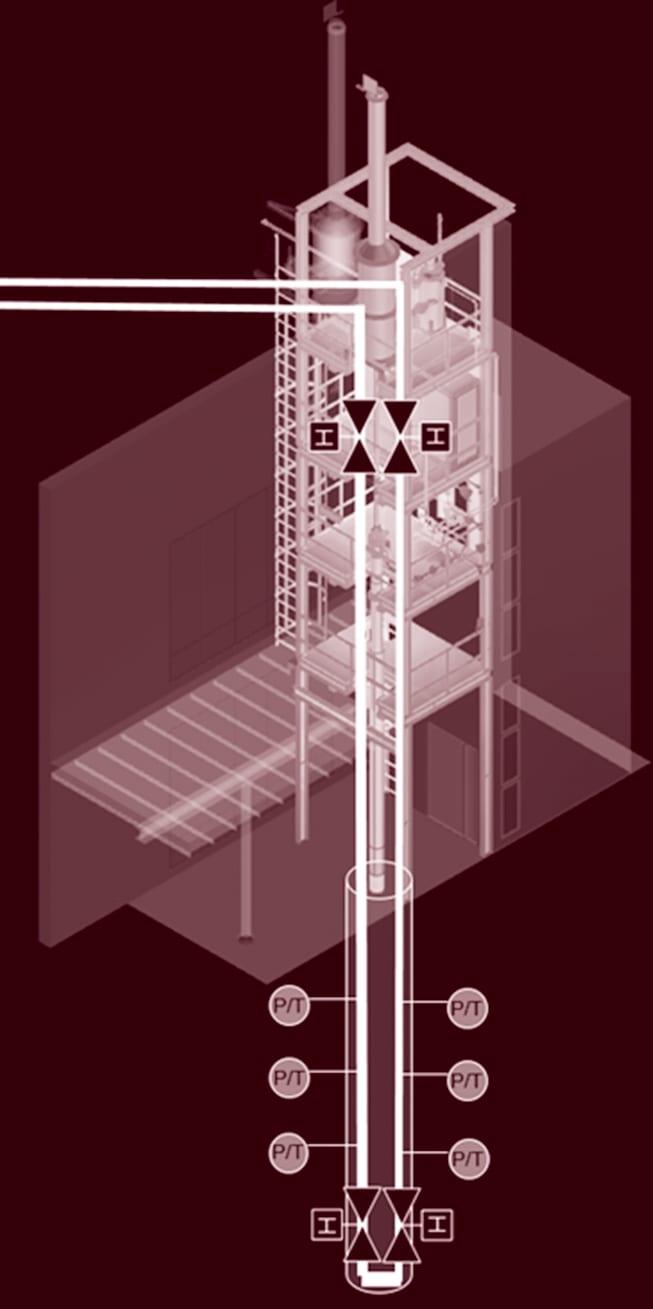

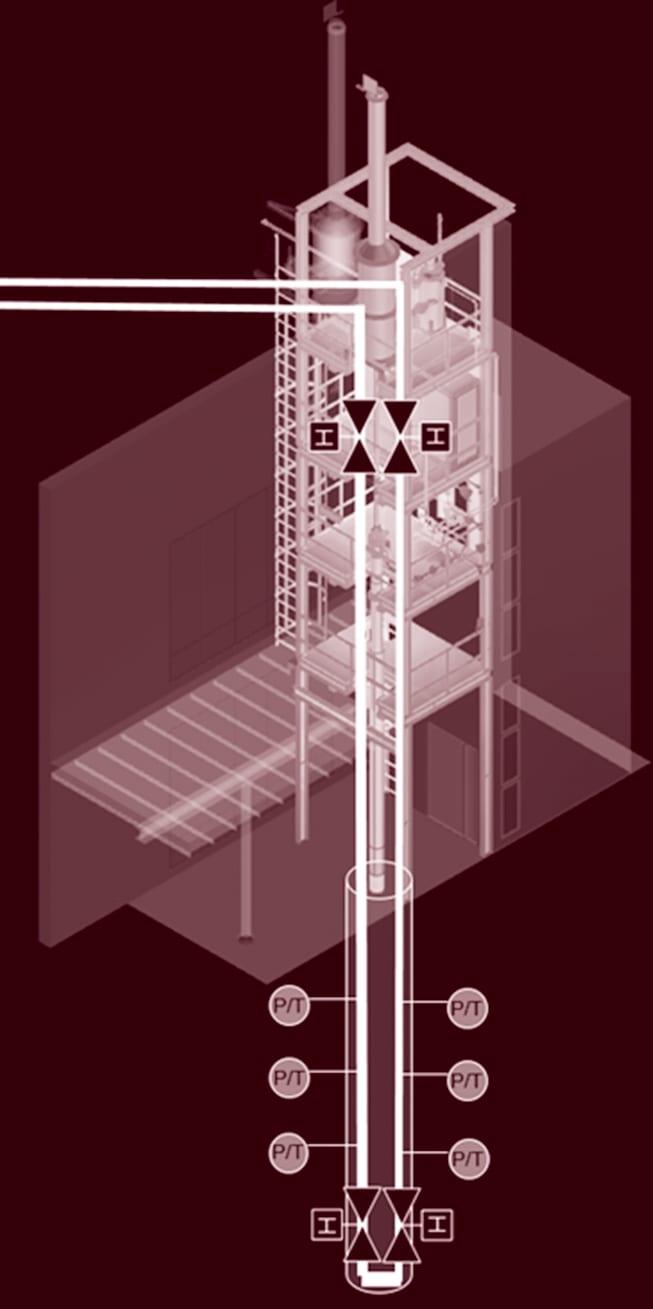

Eget testanlegg på Tiller

LedaFlow handler ikke bare om videreutvikling av et software-program, men også forsøk i et fysisk anlegg som er bygget for å teste CO2 i rør.

– Vi er nødt til å ha gode forsøksdata, ellers blir alt bare ren gjetning, sier forsker i Sintef, Ivar Eskerud Smith.

Sintef har et flerfaselaboratorium på Tiller og anlegget DeFACTO på Gløshaugen i Trondheim, hvor de sender CO2 90 meter ned i bakken i en U-formet sløyfe. Den er utstyrt med over hundre sensorer for trykk og temperatur som gjør nøyaktige målinger. Sløyfen er koblet til en annen horisontal sløyfe med kontrollerte parametre som trykk og gass-til-væske-balanse. Forskerens jobb er å analysere alle data de får inn. Resultatene av eksperimentene sendes til Ludivine Rossvolls team, som gjenskaper dem i digitale Ledaflow.

– Vi sender både ren karbondioksid og CO2 med urenheter ned i U-sløyfen. Sistnevnte er mest realistisk, du får aldri skilt ut hundre prosent av urenhetene, noe vi må ta høyde for siden det kompliserer prosessene i rørene, forklarer Smith.

Horizontal CO2 flow loop

(used for conditioning)

90 m deep

Own test facility at Tiller

LedaFlow is not just a software modeling program. The LedaFlow team are also conducting experiments at a physical facility designed to test how CO2 acts in pipes.

"We need good experimental data, otherwise everything is just pure guesswork," says researcher at Norwegian research institution SINTEF, Ivar Eskerud Smith. In addtion to its multiphase laboratory at Tiller, SINTEF has the DeFACTO facility at Gløshaugen in Trondheim, where they send CO2 90 meters down into the ground in a U-shaped loop. It is equipped with over 100 pressure and temperature sensors that provide accurate data measurements. The loop is connected to another horizontal flow loop used for conditioning, with controlled parameters such as pressure and gas-to-liquid balance.

Smith's job is to analyze all the data they receive. The results of the experiments are sent to Ludivine Rossvoll's team, who recreate them digitally in Ledaflow. "We send both pure CO2 and CO2 with impurities down into the U-loop. The latter gas is more realistic, as you never separate out 100 percent of the impurities. This something we must take into account because it complicates processes in the pipes," explains Smith. "But it's not like CCS will solve all the world's problems and be a silver bullet allowing us to continue pumping oil and consuming as before."

Horizontal CO2 flow loop

(used for conditioning)

"If we can use CCS in industries that produce coal, steel, and ammonia, we can reduce some of what would otherwise be released into the atmosphere. The goal is for CCS to cut 14 percent by 2050, but we have much more emissions than this. We continue to consume, fight wars, and cut down trees," says Ludivine Rossvoll.

"When I started working with CCS, I quickly realized that this is just medicine. Right now, it's extremely important to slow down emissions, and it's urgent. But carbon capture is not the solution. We can't continue as before and just hide away what we don't want. This is not instead of, but in addition to, other measures."

"Right now, it's extremely important to slow down emissions, and it's urgent..."

"If we can use CCS in industries that produce coal, steel, and ammonia, we can reduce some of what would otherwise be released into the atmosphere. The goal is for CCS to cut 14 percent by 2050, but we have much more emissions than this. We continue to consume, fight wars, and cut down trees," says Ludivine Rossvoll.

"When I started working with CCS, I quickly realized that this is just medicine. Right now, it's extremely important to slow down emissions, and it's urgent. But carbon capture is not the solution. We can't continue as before and just hide away what we don't want. This is not instead of, but in addition to, other measures."

"Right now, it's extremely important to slow down emissions, and it's urgent..."

Kongsberg Digital and CO2Flow

CCS stands for carbon capture and storage, which consists of filtering out CO2 that would normally be released into the atmosphere, compressing it into liquid form, then transporting and storing it in reservoirs deep underground, preferably under the seabed.

Kongsberg Digital is part of an ongoing research collaboration (CO2Flow) alongside energy companies ConocoPhillips, TotalEnergies, Equinor, ExxonMobil Technology & Engineering, Wintershall Dea, Petrobras, AkerBP, as well as Kongsberg Digital, SINTEF Industri and SINTEF Energi to further develop LedaFlow.

It is best to transport and store CO2 as a liquid as liquid takes up less space than gas. However, as it travels along long pipes, changes can occur due to, among other things, pressure and temperature change, which can, for example, cause some of the liquid to turn back into gas. LedaFlow can simulate exactly how CO2 will behave in the pipes.

Kongsberg Digital and CO2Flow

CCS stands for carbon capture and storage, which consists of filtering out CO2 that would normally be released into the atmosphere, compressing it into liquid form, then transporting and storing it in reservoirs deep underground, preferably under the seabed.

Kongsberg Digital is part of an

ongoing research collaboration (CO2Flow) alongside energy companies ConocoPhillips, TotalEnergies, Equinor, ExxonMobil Technology & Engineering, Wintershall Dea, Petrobras, AkerBP, as well as Kongsberg Digital, SINTEF Industri

and SINTEF Energi to further

develop LedaFlow.

It is best to transport and store CO2 as a liquid as liquid takes up less space than gas. However, as it travels along long pipes, changes can occur due to, among other things, pressure and temperature change, which can, for example, cause some of the liquid to turn back into gas. LedaFlow can simulate exactly how CO2 will behave in the pipes.

More stories from Kongsberg Gruppen

HISTORIE